Polyester vs nylon backpack

The fabric used for a backpack, tool bag or other bag is very important. Before you decide what material to use it helps to understand more of the benefits and characteristics of the material and how to test the material.

Let us begin with the difference between the two most used materials.

Polyester vs nylon what is the difference?

The distinctions between nylon and polyester in short. The overall performance of nylon is better than polyester, but the cost is higher than polyester. Nylon products perform better than polyester products in terms of abrasion resistance, strength, color fastness, glossiness, etc., and do not wrinkle easily.

The touch of nylon is soft, while polyester feels hard!

Polyester vs nylon more in depth

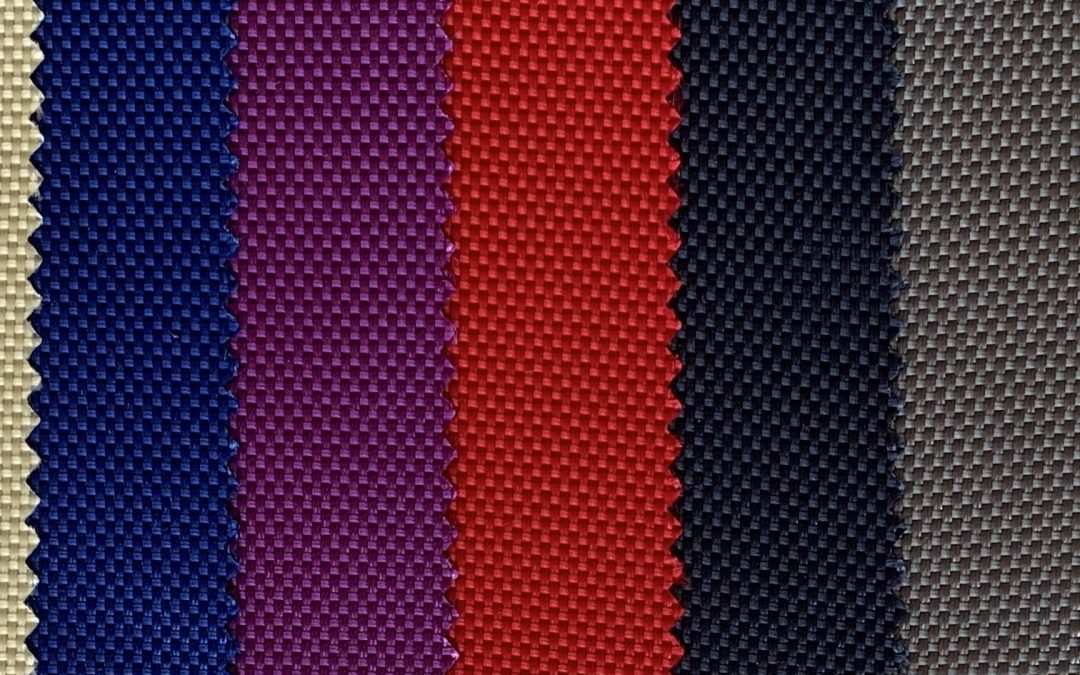

To be able to choose between a Polyester vs a nylon backpack, we zoom in the differences more in detail. Check the image and description of a Polyester backpack as example:

- Price

- Roughly spoken the price of nylon price is twice the price of polyester

- Touch

- Nylon feels smoother and softer than polyester

- Abrasion resistance

- The abrasion resistance of Nylon compared with Polyester is not much different

- Elasticity

- Nylon is not very elastic, but polyester is completely lacking in elasticity

- Dying

- The material made of nylon is more difficult to dye than polyester

Properties of the fabrics

Polyester (1) Mechanical properties: high breaking strength, high elongation; high initial modulus; good elastic recovery; stiff fabric, good abrasion resistance, good dimensional stability. (2) Poor moisture absorption and dyeing W=0.4%; cannot be dyed at room temperature. (3) thermal properties high melting point 255-265°C; good heat resistance and thermal stability (4) optical properties, good light resistance, second only to acrylic (5) acid resistance, not strong alkali resistance, no mold, and no moth (6) density: 1.38 g/cm3

Nylon (1) mechanical properties (1) breaking strength, flexural strength is high, elongation is large; initial modulus is low, fracture work is large; good elasticity, good abrasion resistance, fabric conform ability and stiffness is poor. (2) moisture absorption dyeing W = 4.5%, better than polyester (3) thermal properties poor heat resistance; safe use temperature: less than 93°C; melting point: 215°C (4) poor light resistance (5) alkali resistance not acid resistance (6) small density: 1.14 g/cm3.

Now there are imitation nylons on the market, the appearance with the real nylon fabric is very similar, but the quality is different.

Denier or XXXD

Denier is a unit of measurement used to determine the fiber thickness of individual threads or filaments used in the creation of textiles and fabrics. Fabrics with a high denier count tend to be thick, sturdy, and durable. Fabrics with a low denier count tend to be sheer, soft, and silky.

Polyester aka polyethylene terephthalate?

Polyester, or polyethylene terephthalate, has a good air permeability and moisture wicking. Polyethylene terephthalate manages to quickly move (wicking) water like sweat to the fabric’s outer surface and is drying rapidly so that the water doesn’t saturate the fabric. This fabric also has a strong resistance to acid, alkali, and UV radiation. The most common used denier for polyester is 75D. but you will also find 150D, 300D, 600D, 1200D, and 1800D. The appearance of polyester is darker than nylon, and the fabric is rougher as texture.

Nylon composition of polyamides

Nylon is a polyamide fiber. The advantages of polyamides are high strength, significant abrasion resistance, strong chemical resistance and good resistance to deformation, and anti-aging. The disadvantage is that the feel of the texture is very hard. The most famous nylon fabrics are PERTEX and CORDURA. In general, most nylon is 70D, depending on the purpose of the bag you will also see 210D, 420D, 840D, 1680D. The fabric has a glossy bright appearance and, when you touch the surface, it feels very soft.

What fabric is better for backpacks, Polyester or Nylon?

When you must decide what fabric is better for your customized backpacks, you need to keep the purpose in mind. When the backpacks are a promotional gift, we recommend polyester because the cost is lower. However, when you want to bring an outdoor sports backpack on the market, we recommend nylon or another durable fabric.

How to test what fabric the backpack is made from?

The easiest way to test if the material is nylon and polyester is going for the burning assessment method! When burning polyethylene terephthalate will show very dark black smoke, while nylon will show white smoke when burning. Test the residue, the residue of polyester will break when you touch it, nylon residue will become plastic!

The test in detail

Nylon, when held near the flame quickly curls and melts into a white gel. Nylon will burn without showing a flame, and difficult to continue to burn. The fabric will emit a smell like celery, and after cooling down a light brown molten material will remain that is not easy to grind.

How does the test look like for nylon?

Close to the flame: combustible softening and shrinking. In the flame: curling, melting, slow burning, producing small bubbles. The flame is very small and colors blue. When you remove the flame: fabric stops burning and is self-extinguishes. The burning odor: Amino taste or celery taste. Residue characteristics: ash course hard and a black round ball shape, not easy to crush with fingers.

Polyester is easy to ignite. When it melts the fabric will shrink. When polyester is burning it will melt, show a black smoke with yellow flame and emitting an aromatic odor. After burning the ashes will have a color that is black/brown and feeling hard and can be twisted with the fingers.

How does the test look like for polyester?

Close to the flame: – softening, molten curl. In the flame: – molten, slow burning, with a yellow flame, flame edge blue color, black smoke from the top of the flame. Leaving the flame: continue to burn, sometimes the material stops burning and I self-extinguishing. Burning odor: slightly aromatic or sweet smell. Residue characteristics: ash process hard and black ball-shaped, not easy to crush with fingers

The conclusion

One can use both materials for a backpack, important is the purpose and final use of the bag. Our sales team is ready to assist you.